We have core expertise in the development and proprietary technology for fabrication of microfluidic devices made of a variety of material systems. Materials for microfluidic chip fabrication include:

Device Materials

We work with a variety of materials for microfluidic chip fabrication

Click on the picture behind to see the difference

PDMS or Polydimethylsiloxane

PDMS is the most widely used silicon-based organic polymer. PDMS is a rubber like elastomer, optically clear, bio compatible, inert, non-toxic, and non-flammable. PDMS chips are the most used platforms in Microfluidics.

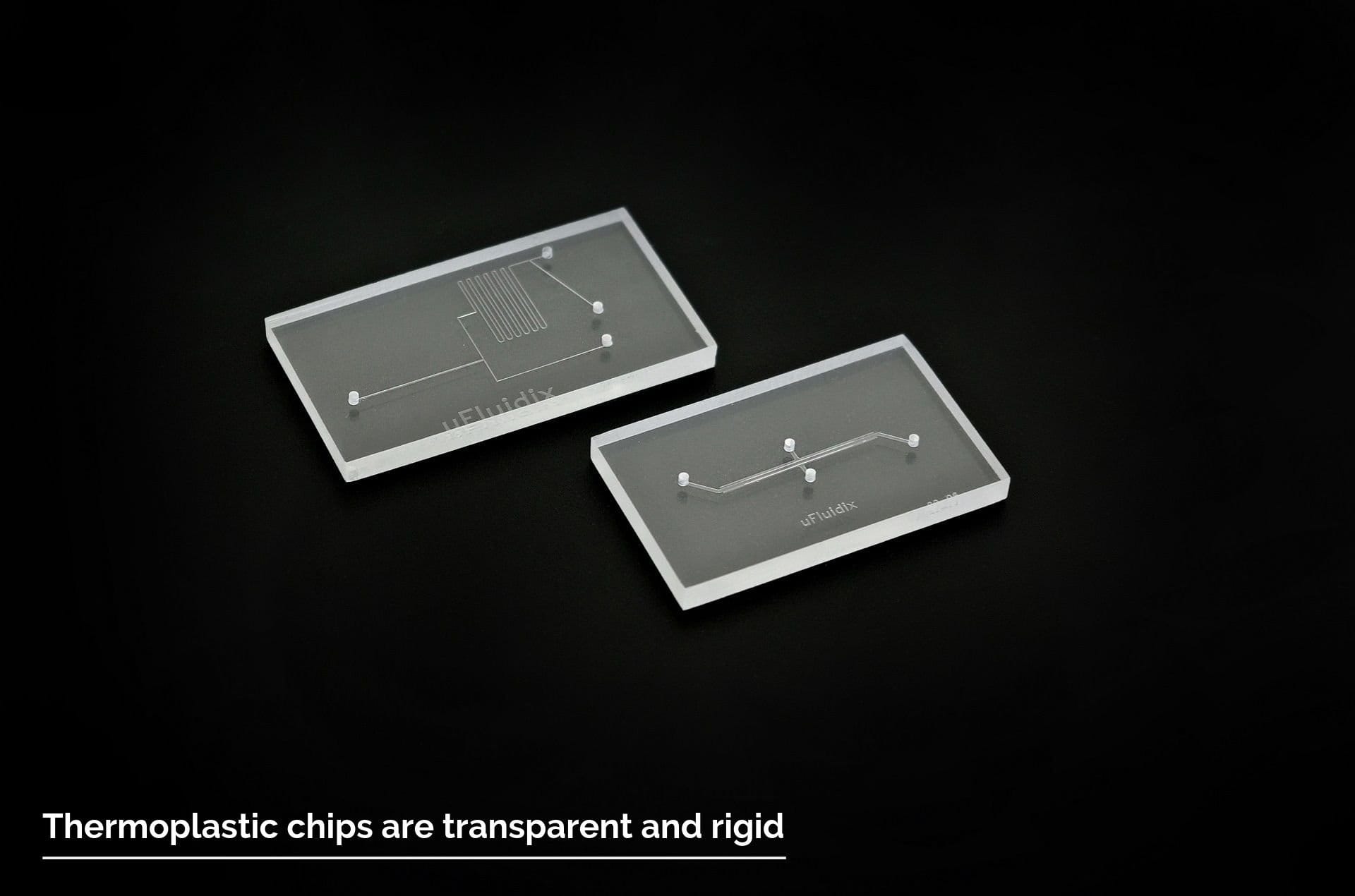

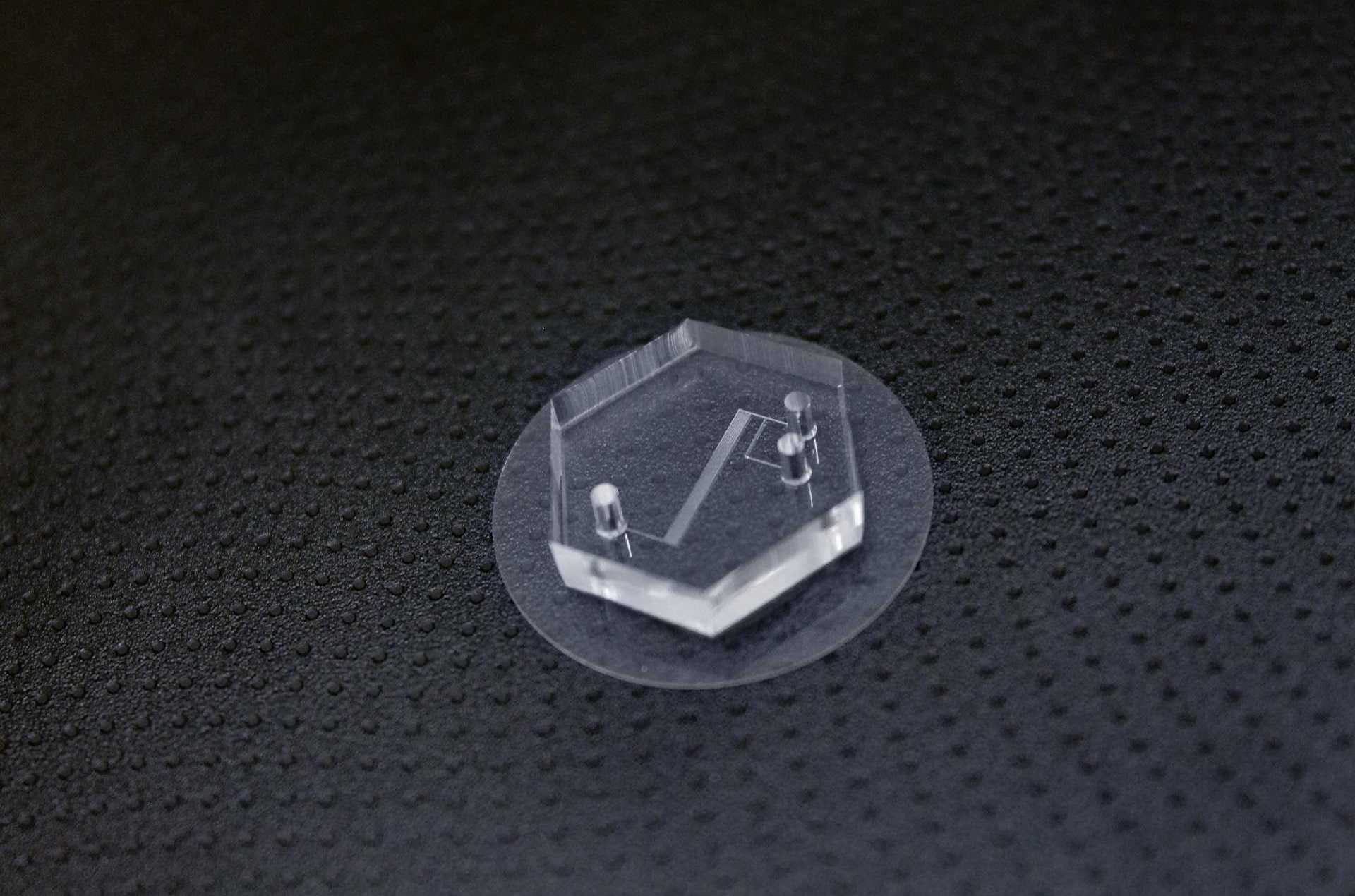

Thermoplastics:

Thermoplastics are mostly used in Microfluidics where a rigid microfluidic chip is needed. Thermoplastic also used for high volume cartridges used in diagnostics.

- PMMA – Polymethyl methacrylate, a.k.a acrylic glass or Plexiglass.

- PC – Polycarbonate, such as Makrolon or Lexan.

- PS – Polystyrene, popular plastic used for cell culture containers such as Petri Dish.

- COC – Cyclic Olefin Copolymer, is a thermoplastic polymer.

- COP – Cyclic Olefin Polymers, is a thermoplastic polymer.

Click on the picture behind to see another chip

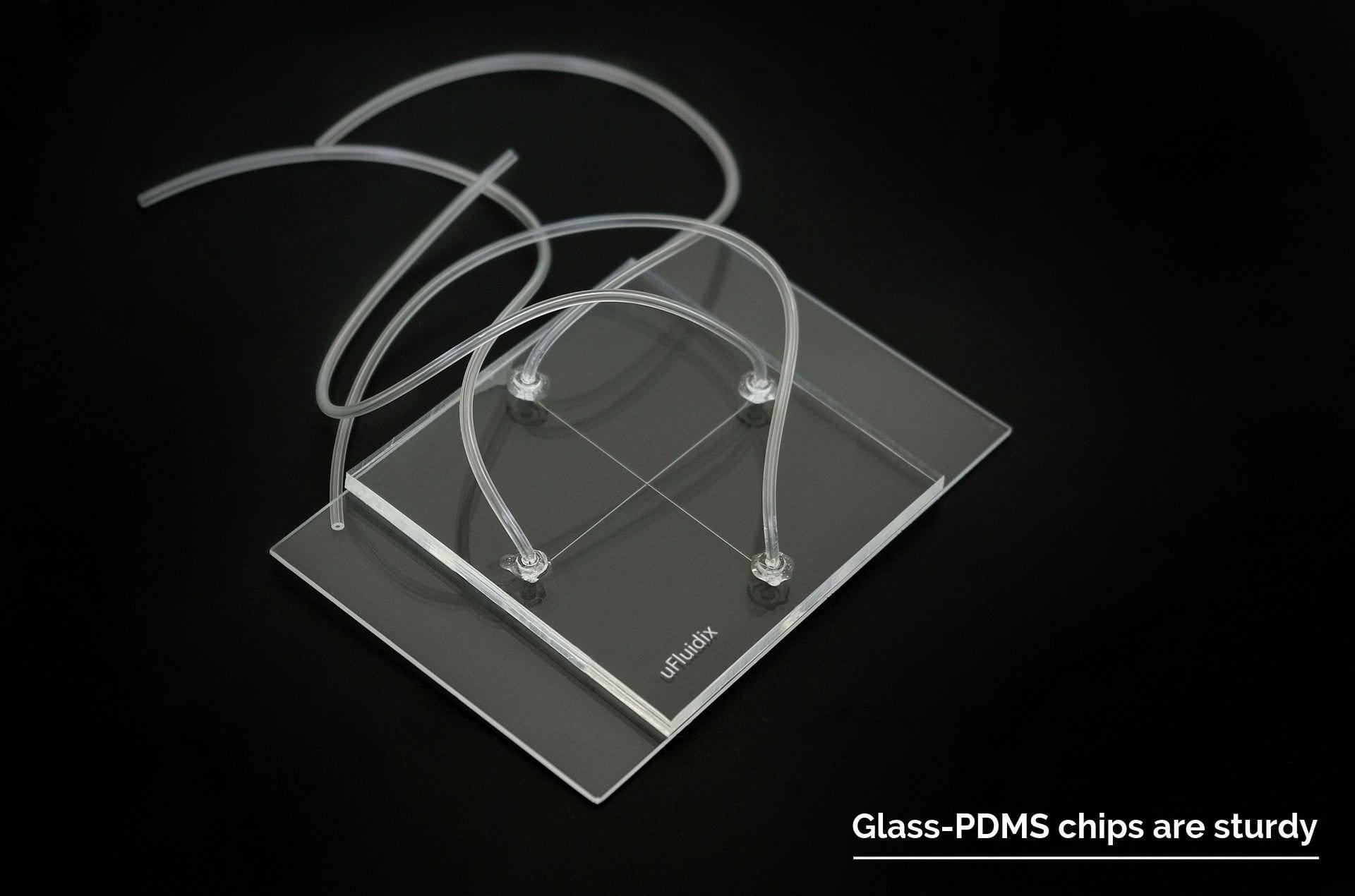

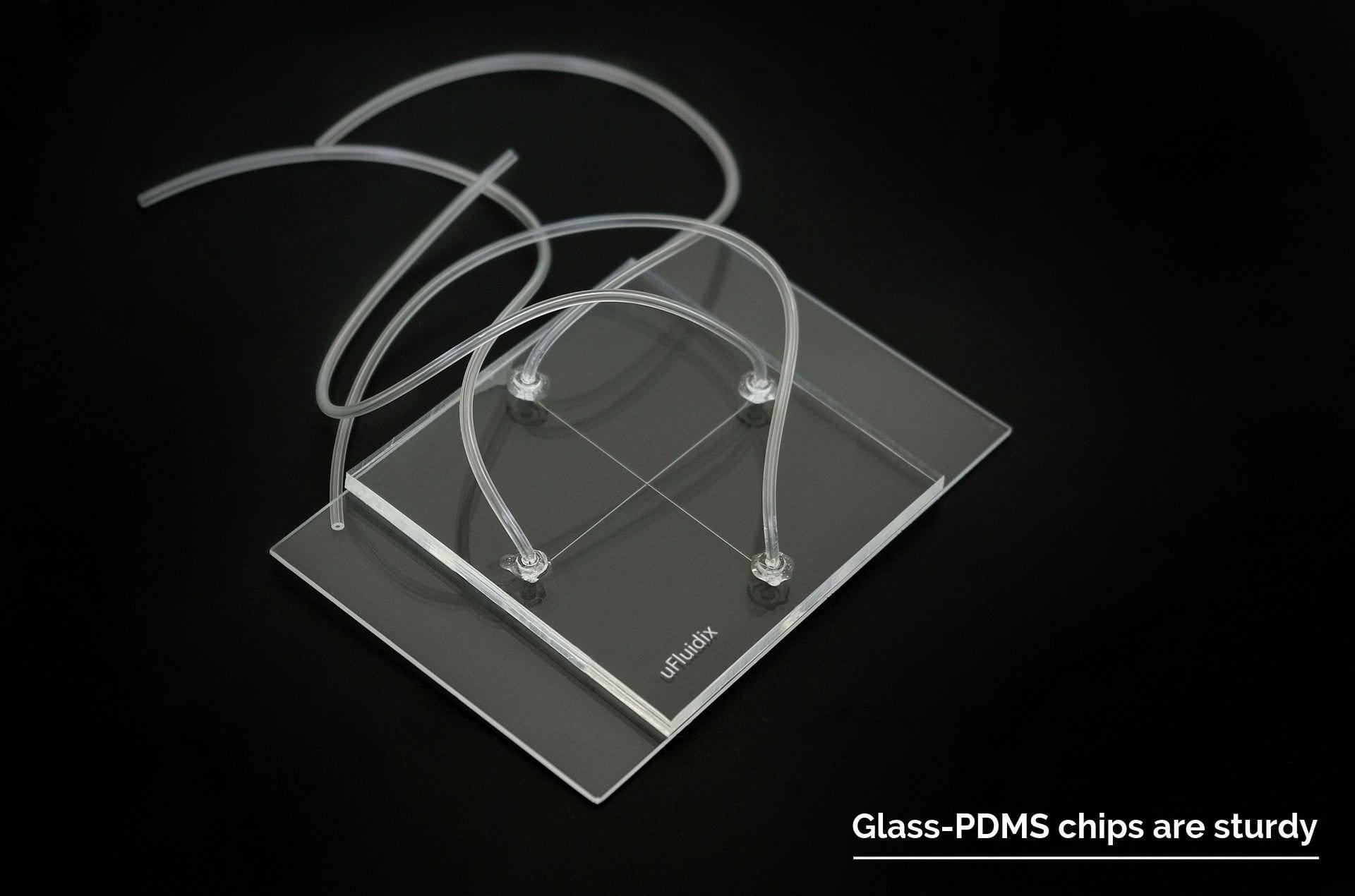

Glass-PDMS

Since PDMS parts have rubber-like mechanical properties, they are not stiff enough for handling especially when the parts are less than 1 mm (0.04”) thick. Therefore, these PDMS parts are often bonded to glass microscope slide or thin glass cover slips, or custom size glass substrates. Sufficient bonding strength between PDMS and glass is needed for continuous flow microfluidics applications, otherwise the fluid would leak out of the microfluidic channel. uFluidix has special expertise in bonding and sealing PDMS parts to glass and variety of other substrates for the manufacture of microfluidic devices. Glass and PDMs have very different surface properties. For most microfluidics applications the difference in surface properties does not cause issues, however for some applications such as droplet microfluidics, sometimes glass surface needs to be altered to become hydrophobic like PDMS. Alternatively for some applications such as cell culture or capillary action driven flow PDMS surface needs to become hydrophilic like glass.