27 May Advancing Protein Solubility Optimization with Ultrahigh-Throughput Microfluidics

Every day, scientific research is advancing our understanding of how drugs can be improved and made more effective. One particularly exciting development involves protein-based drugs, which hold immense promise in the fight against numerous diseases. Protein-based biologics are the new stars of the pharmaceutical industry, offering the potential for highly specific, low-toxicity treatments. These biologics, however, must often be formulated to elevated concentrations, and insufficient solubility can become a critical bottleneck in the drug development pipeline. Recently, a team of researchers have made a significant stride in this area, employing microfluidics to transform protein solubility screening.

Traditional methods of protein solubility screening have been laborious and material-intensive, often limiting their throughput. The team’s innovative ultrahigh-throughput microfluidic chip offers a promising solution to this limitation. This platform can create, incubate, and measure samples in mere minutes, using only 20 μg of protein. This remarkable technology represents a >10-fold improvement in protein usage and yields an impressive 10,000 data points, a 1000-fold improvement in comparison to previous methods.

The Power of Microfluidics

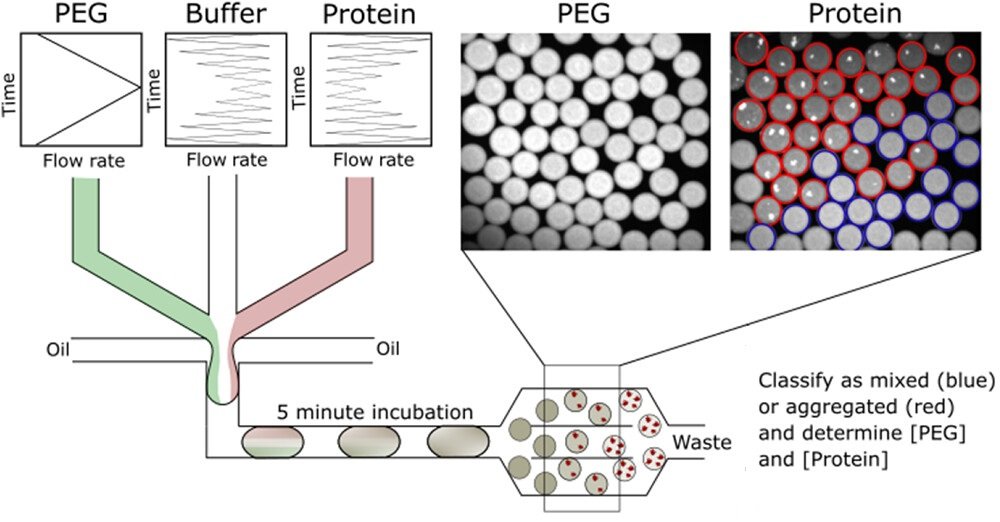

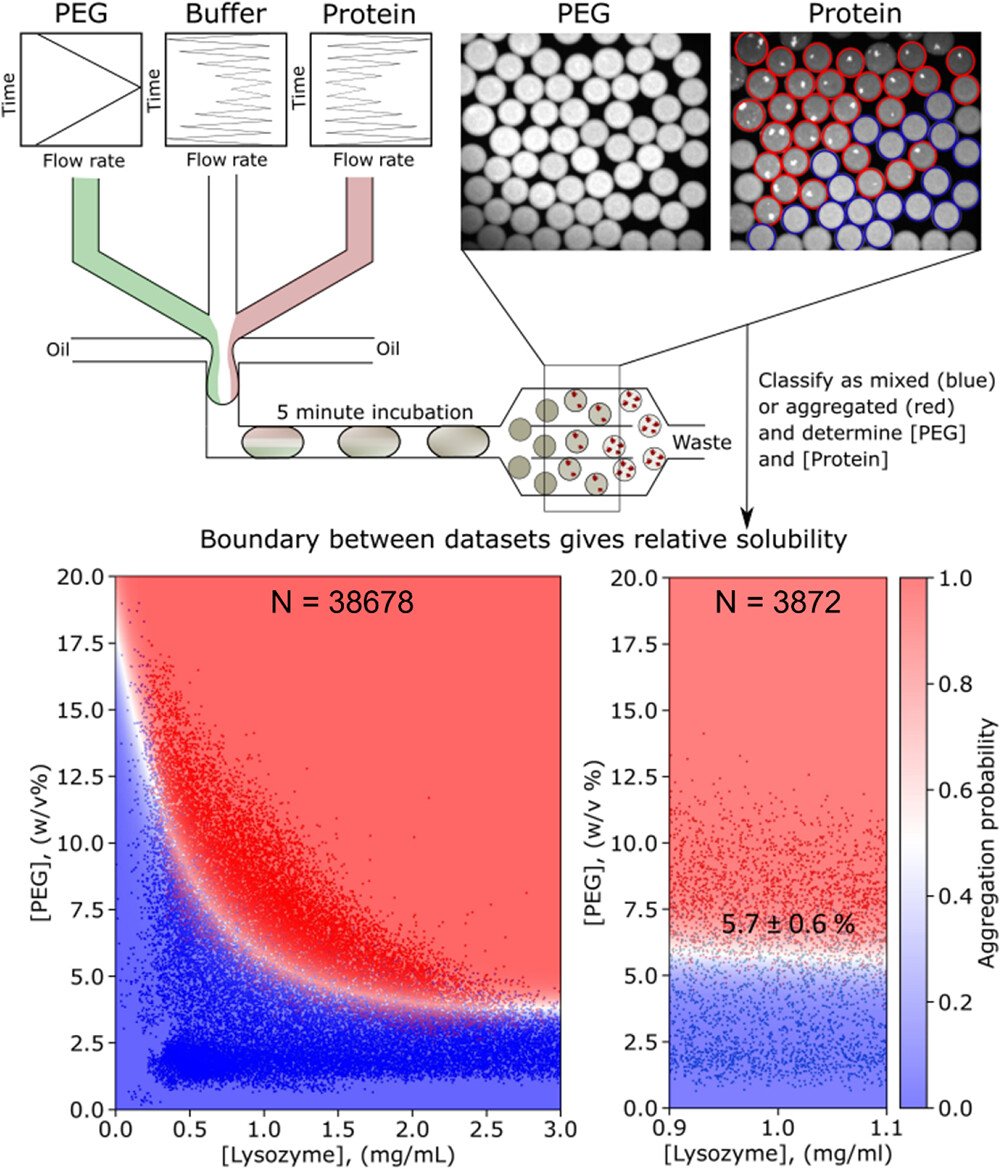

Microfluidics, a field that manipulates fluids at a miniature scale, offers tremendous advantages in protein solubility research. The newly developed droplet microfluidic platform empowers researchers to generate thousands of microdroplets, each representing a unique data point for solubility analysis. By precisely controlling flow rates and leveraging advanced imaging techniques, protein solubility can be accurately measured within these microdroplets. This approach minimizes sample volumes and dramatically reduces measurement time, making it feasible to explore a wide range of formulation conditions efficiently.

“Here, we report an ultrahigh-throughput microfluidic platform for protein solubility screening. In comparison with previous methods, this microfluidic platform can make, incubate, and measure samples in a few minutes, uses just 20 μg of protein (>10-fold improvement), and yields 10,000 data points (1000-fold improvement). This allows quantitative comparison of formulation excipients, such as sodium chloride, polysorbate, histidine, arginine, and sucrose. “, the authors explained.

Unleashing the Potential of Multidimensional Screening

One of the key strengths of the proposed PDMS-based microfluidic device is its ability to conduct multidimensional screenings of formulation parameters. By simultaneously varying multiple variables, researchers gain a deeper understanding of how solubility is influenced by factors such as pH, ionic strength, and additive combinations. This approach goes beyond traditional screening methods, allowing for a more comprehensive exploration of the formulation space. With the microfluidic chip, solubility optimization experiments can be conducted with greater precision and efficiency, accelerating the drug development process.

Diving into Experimental Details

The microfabrication of the microfluidic chip was done according to the standard microfabriation techniques. In a compelling display of the capabilities of the microfabricated chips, researchers varied concentrations of two excipients – NaCl and arginine, which enhance protein physical stability. They conducted the experiment keeping the amount of protein and Polyethylene glycol (PEG) constant. The experiment showed that the absence of NaCl and arginine leads to aggregate formation, while their addition improved solubility, transforming the solution into a mixed state. By analyzing the linear slope of the solubility versus additive concentration graph, it was concluded that NaCl and arginine work together linearly to improve solubility.

Interestingly, the research also indicated that arginine is more efficient at improving solubility than NaCl. These findings were consistent across various concentrations of PEG, further underlining the reliability of the microfluidic platform in investigating the combinatorial effects of excipients on protein solubility.

“Setup for measuring protein solubility in an ultrahigh-throughput aggregation assay. Water-in-oil droplets of ∼100 pL are created by mixing solutions containing protein, buffer, and PEG at various ratios. The droplets are incubated for 5 min and imaged at the wavelengths corresponding to the fluorescent dyes added solutions. A Python script (28) is used to determine the concentration of each component and to classify them as containing a mixed solution (blue) or aggregates (red). We fit the data with a support-vector machine algorithm and determine the aggregation probability. This procedure enables us to determine the phase boundary (white region) and the relative solubility value. At 1 mg/mL lysozyme at pH = 7, we find a relative solubility of 5.7 ± 0.6% PEG. The 2D graph on the left and the selection on the right display 38,678 and 3872 data points, respectively.” Reproduced from Nadia A. Erkamp, Marc Oeller, Tomas Sneideris, Hannes Ausserwoger, Aviad Levin, Timothy J. Welsh, Runzhang Qi, Daoyuan Qian, Nikolai Lorenzen, Hongjia Zhu, Pietro Sormanni, Michele Vendruscolo, and Tuomas P.J. Knowles Analytical Chemistry 2023 95 (12), 5362-536. under Creative Commons Attribution 4.0 International License.

Optimization and Mutational Variants

An additional feature of this platform is its ability to optimize the pH of a formulation. Researchers evaluated the solubility of Bovine Serum Albumin (BSA) buffered at pH levels ranging from 4 to 9. They observed that increasing the pH significantly improved protein solubility, with solubility at pH = 9 being exceptionally high.

The platform also measured the solubility of different protein mutants, an important strategy to improve protein solubility while retaining its functionality. For instance, the IgG4 antibody and six of its mutational variants were evaluated. The results revealed that variants predicted to be more soluble by the CamSol method indeed demonstrated higher solubility, confirming the platform’s utility in accurately ranking solubility among protein variants.

Looking Ahead

The ultrahigh-throughput microfluidic chip represents a groundbreaking advancement in protein solubility optimization. By combining small sample volumes, rapid measurements, and precise analysis, this technology empowers researchers to explore formulation parameters and excipients with unparalleled efficiency. The platform’s ability to conduct multidimensional screenings and rank excipients based on effectiveness revolutionizes formulation design and streamlines the drug development process. With its comprehensive insights into biotherapeutic solubility and additive interactions, this microfluidic platform opens new horizons for the development of effective protein-based drugs.

In conclusion, this innovative microfluidic platform is setting a new standard in protein-based drug development, providing scientists with a microfluidic tool that is not only cost-effective but also extremely precise even when the variants differ by just a few point mutations. The future looks promising for the development of new protein-based drugs, and we eagerly await the next breakthrough in this fascinating field.

“Our microfluidic platform provides a highly quantitative strategy for improving a wide range of aspects influencing protein solubility and can aid in the development of new protein-based drugs. “, the authors explained.

Figures are reproduced from Nadia A. Erkamp, Marc Oeller, Tomas Sneideris, Hannes Ausserwoger, Aviad Levin, Timothy J. Welsh, Runzhang Qi, Daoyuan Qian, Nikolai Lorenzen, Hongjia Zhu, Pietro Sormanni, Michele Vendruscolo, and Tuomas P.J. Knowles Analytical Chemistry 2023 95 (12), 5362-5368 DOI: 10.1021/acs.analchem.2c05495 under Creative Commons Attribution 4.0 International License.

Read the original article: Multidimensional Protein Solubility Optimization with an Ultrahigh-Throughput Microfluidic Platform