01 Apr High-Throughput Screening of Individual Catalyst Particles Using Microreactors

Catalysts are substances that accelerate chemical reactions without being consumed in the process. They are critical to a wide range of industrial processes, including oil refining, polymer production, and pharmaceutical manufacturing. However, not all catalyst particles within a given batch have the same level of activity. As such, being able to accurately assess the activity of individual particles is important for optimizing catalytic processes. Microfluidic devices have been shown to be useful tools for screening the activity of individual particles, and the authors of a recent study published in Microsystems and Nanoengineering have developed a new microfluidic chip that enables high-throughput screening of individual fluid catalytic cracking (FCC) equilibrium catalyst (ECAT) particles based on their Brønsted acidities.

“With this high-throughput single particle screening method, a compromise between bulk measurements that average the characteristics of multiple particles and single particle measurements that lack statistical relevance has been developed and demonstrated. “, the authors explained.

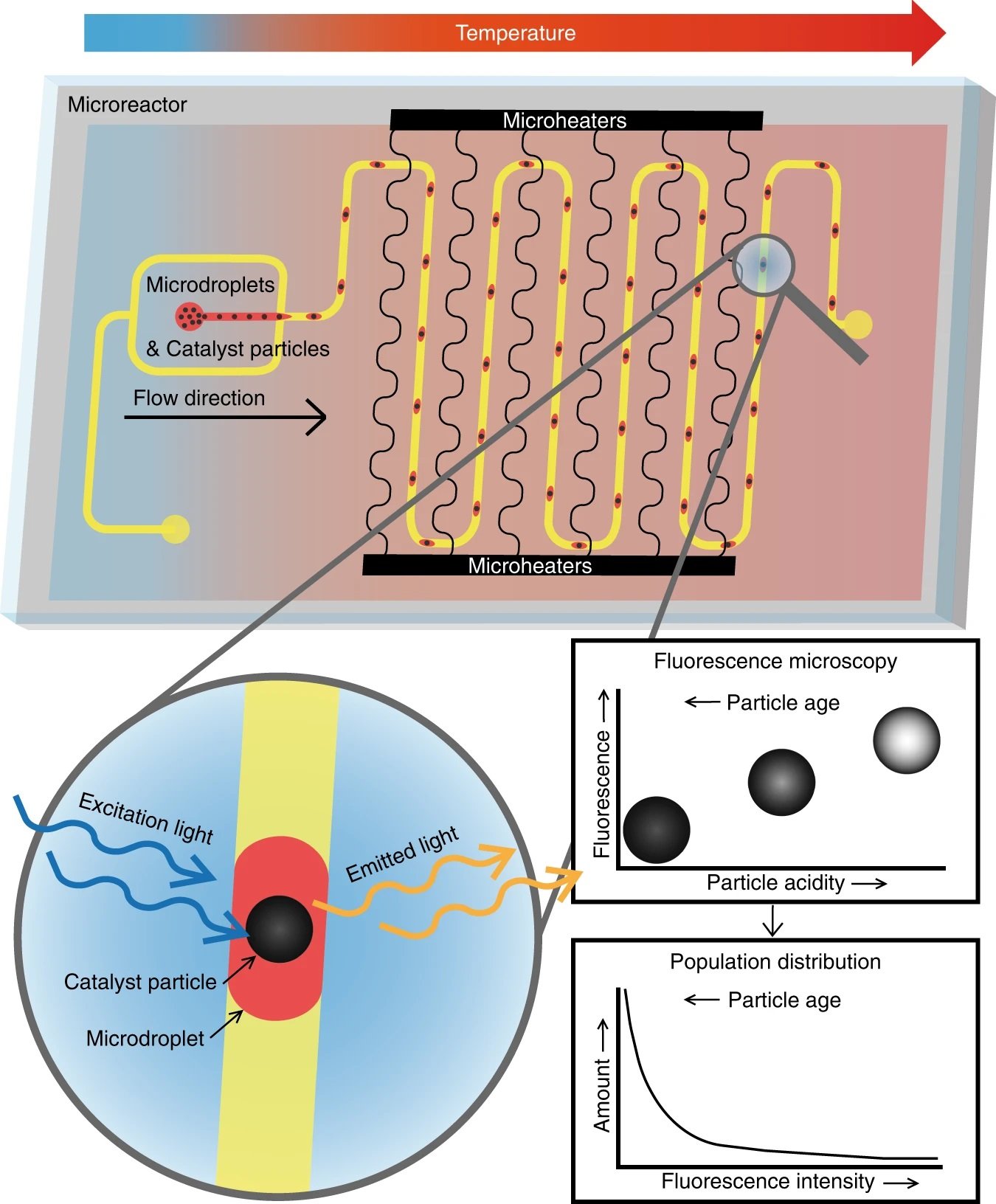

“Fluorescence microscopy can be used to screen fluorescent product formation in the catalyst particles. The expected relationships between fluorescence intensity and catalyst particle acidity and age are shown, as is a population distribution of the catalyst particles” Reproduced from Vollenbroek, J.C., Nieuwelink, AE., Bomer, J.G. et al. Droplet microreactor for high-throughput fluorescence-based measurements of single catalyst particle acidity. Microsyst Nanoeng 9, 39 (2023) under Creative Commons Attribution 4.0 International License.

The microfluidic chip, designed and fabricated using microfabrication techniques, contained integrated heaters and temperature sensors, allowing for the tuning of reaction conditions and the optimization of the screening process. The researchers oligomerized 4-methoxystyrene with calcined FCC ECAT particles located inside paraffin oil droplets, using a fluorescent reaction product as an indicator of catalyst acidity. Videos of the fluorescent catalyst particles passing the detection spot were recorded and analyzed with MATLAB.

The results of the study showed that the microfluidic chip provided a compromise between bulk measurements that average the characteristics of multiple particles and single particle measurements that lack statistical relevance. The screening was performed in situ at elevated temperatures up to 95 °C, and ~1000 FCC catalyst particles were detected with an average rate of 1 particle per 2.4 s. This provided statistically relevant results for the single catalyst particle study, given that this number of detected FCC particles was representative of the entire population with a confidence level of 95%.

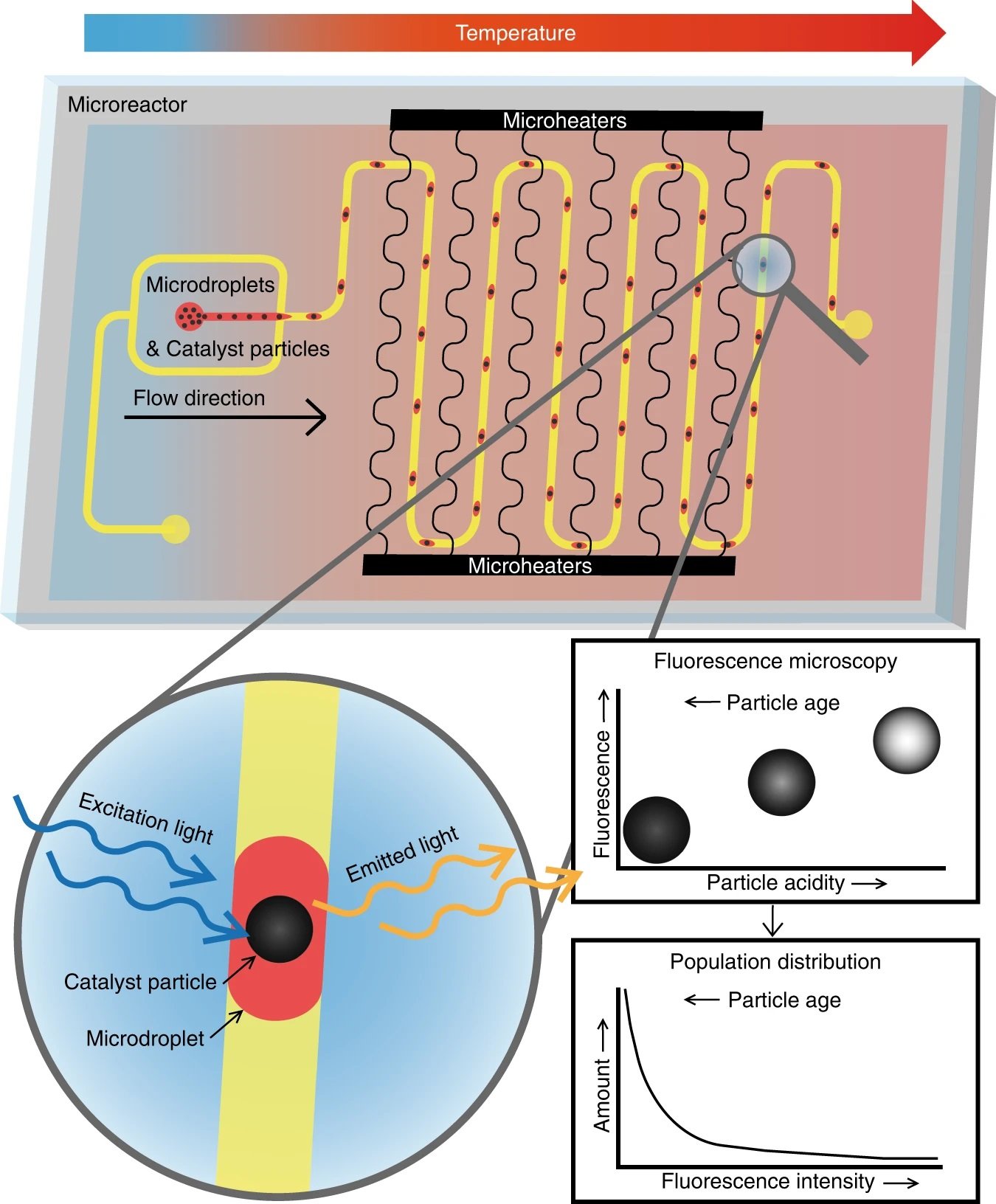

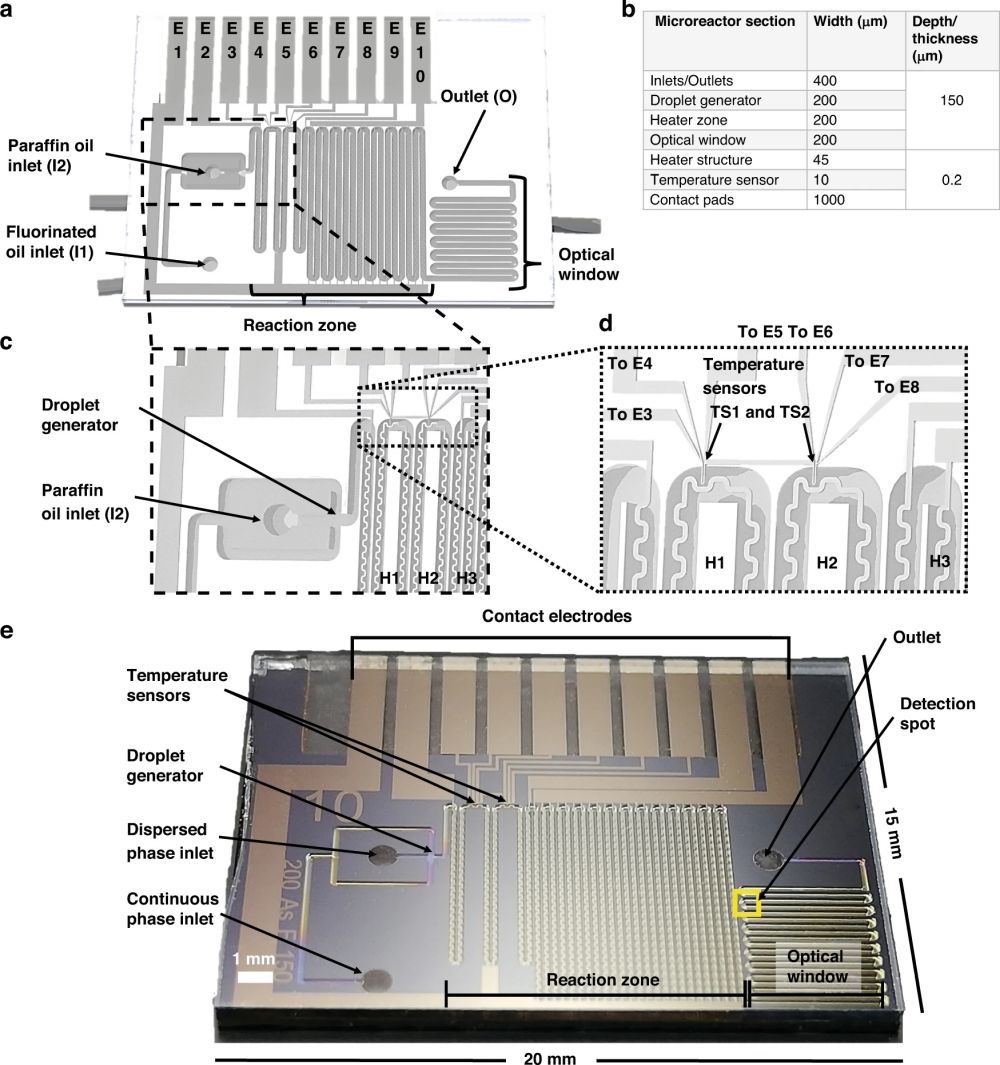

“The channels have widths of 200 µm and depths of 150 µm, the heaters are 45 µm wide and 200 nm thick, and the temperature sensors have widths of 10 µm and thicknesses of 200 nm. All metallic thin-film structures were made from 190 nm platinum (Pt), with a 10 nm tantalum (Ta) adhesion layer. The bottom substrate is silicon (Si) and the top substrate is glass. This figure provides a an overview showing the contact electrodes (E1–E10) for the heater and sensor structures, the flow channel layout, the inlets for the dispersed phase (I1) and continuous phase (I2), and the outlet (O); b the dimensions of the various sections of the droplet microreactor, c a close-up schematic of the droplet generator, showing the flow focusing junction and the inlet for the dispersed phase and the three heaters (H1–H3) that are controlled via electrodes E2 (H1), E9 (H2), and E10 (H3), d a close-up schematic of the temperature sensor structures (TS1 and TS2) and the electrodes used for addressing those structures (E3–E8), and e the droplet microreactor used for the experiments, including the area for fluorescence detection (indicated by the yellow square)” Reproduced from Vollenbroek, J.C., Nieuwelink, AE., Bomer, J.G. et al. Droplet microreactor for high-throughput fluorescence-based measurements of single catalyst particle acidity. Microsyst Nanoeng 9, 39 (2023) under Creative Commons Attribution 4.0 International License.

Overall, this microfluidic device provides valuable information on the age distribution of the catalyst particle mixture and the overall reactor acidity while also providing information on the acidity of individual catalyst particles. The researchers envision that this technique will be used to study the influence of reactor operating conditions on the catalyst particle population or to study the effects of synthesis parameters on the performance of the catalyst particles. This study is an important step towards developing more efficient and effective screening methods for catalyst particles, which have a wide range of applications in the chemical industry.

“We envision that this technique will be used to study the influence of reactor operating conditions on the catalyst particle population or to study the effects of synthesis parameters on the performance of the catalyst particles. Future work could combine on-chip acidity screening with the previously reported fluorescence-based dielectrophoretic sorting of catalyst particles based on their acidity “, the authors concluded.

Figures are reproduced from Vollenbroek, J.C., Nieuwelink, AE., Bomer, J.G. et al. Droplet microreactor for high-throughput fluorescence-based measurements of single catalyst particle acidity. Microsyst Nanoeng 9, 39 (2023). https://doi.org/10.1038/s41378-023-00495-2 under Creative Commons Attribution 4.0 International License.

Read the original article: Droplet microreactor for high-throughput fluorescence-based measurements of single catalyst particle acidity