11 Aug Life Cycle Impacts of Scaling Magnetite Nanoparticle Production with Microfluidics

Magnetite nanoparticles (MNPs) have become valuable in areas ranging from environmental remediation and water treatment to medical diagnostics, electronics, and drug delivery systems. Their unique electrical and magnetic properties, combined with the ability to tailor their size and surface characteristics, make them a versatile material across many industries. In recent years, the synthesis of these nanoparticles using microfluidic chips has attracted significant interest. As the authors explain,

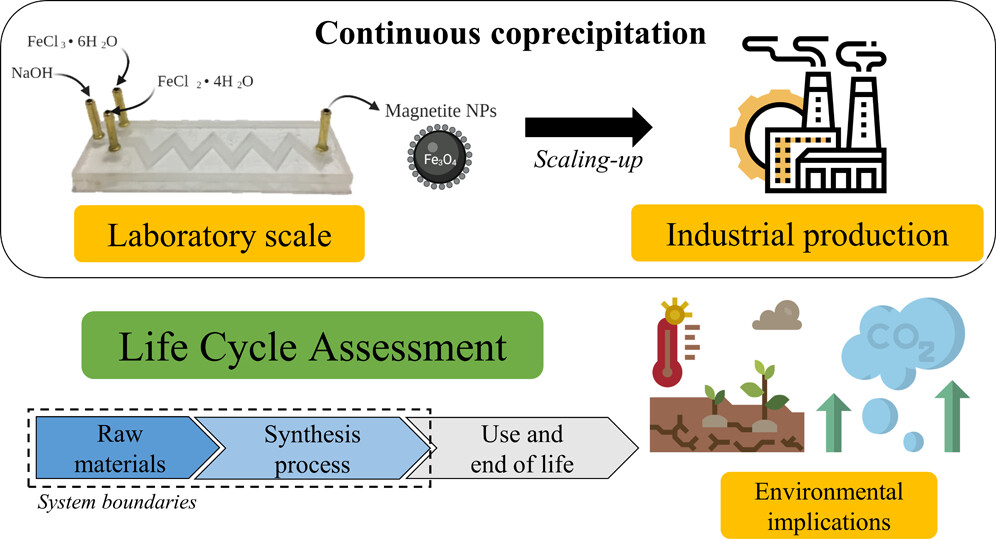

“Emerging technologies such as microfluidic techniques have been adapted to continuously synthesize MNPs showing appealing results, such as a narrower size distribution. Therefore, this approach might become important for producing MNPs to meet industrial requirements. In this study, a life cycle assessment (LCA) is conducted to analyze and evaluate the impacts of the synthesis of MNPs performed in microfluidic devices.”

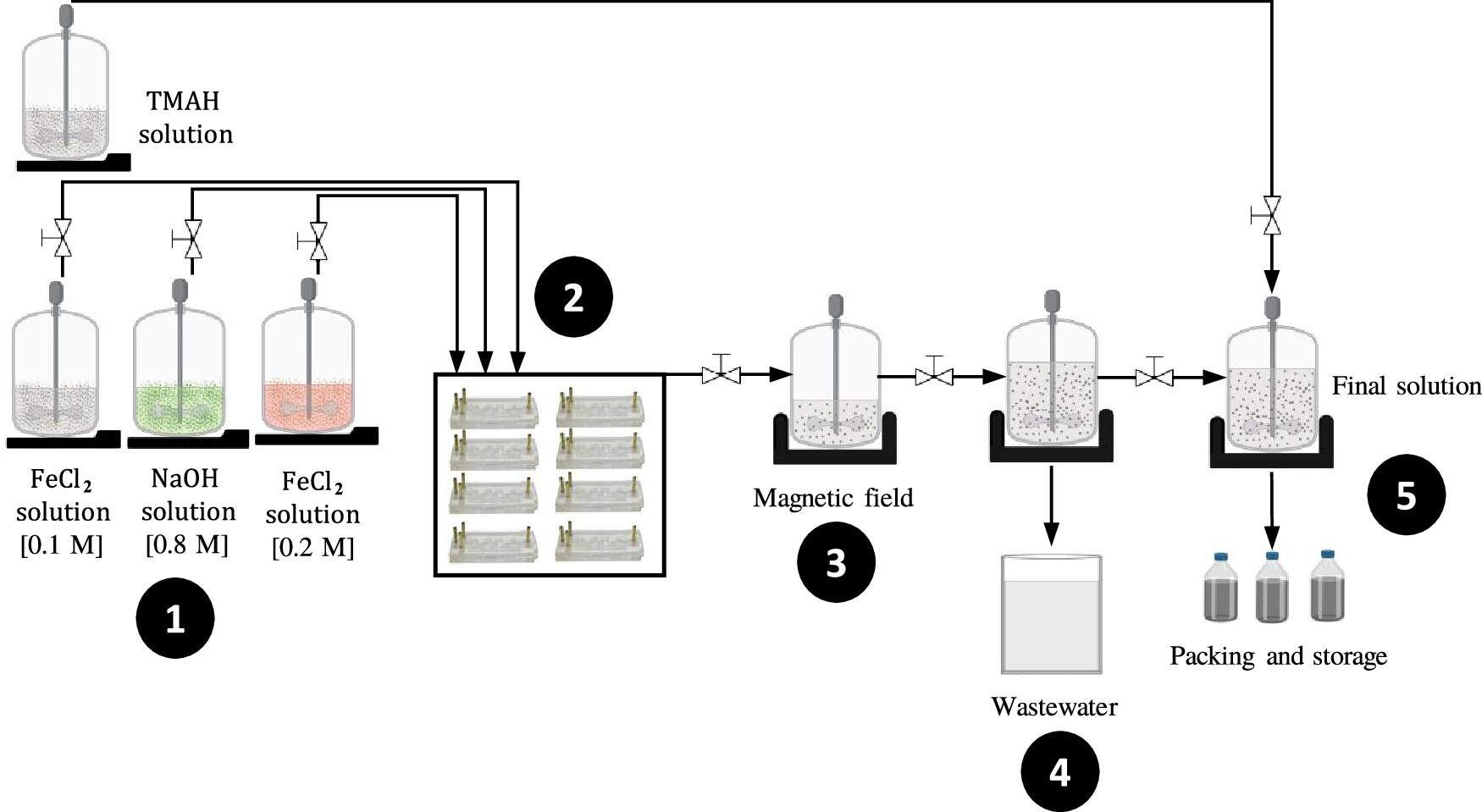

The process examined in the study involved continuous coprecipitation of iron salts inside a custom-built 3D micromixer fabricated from poly(methyl methacrylate) (PMMA) via laser cutting. The microfluidic device featured two inlets: one delivering sodium hydroxide solution and the other delivering a mixture of iron(II) chloride tetrahydrate and iron(III) chloride hexahydrate. Within the microfluidic platform, the streams mixed rapidly, forming magnetite nanoparticles, which were then stabilized with tetramethylammonium hydroxide (TMAH) to prevent agglomeration. The researchers divided the workflow into two main stages: the manufacturing stage, which included the microfabrication of microfluidic devices and the assembly the and their brass rivet connectors, and the operation stage, which encompassed the actual microfluidic synthesis, washing, and conditioning of the nanoparticles.

To explore the environmental consequences of scaling up, the team modeled an industrial facility producing 100 tones of MNPs per year. This microfluidic setup would require more than 11,500 microfluidic devices operating in parallel, supported by large-scale mixing tanks, pumps, magnetic separation units, and storage systems. Their analysis found that at the laboratory scale, manufacturing dominated the environmental footprint, accounting for 97% of the total impact, largely due to the production of brass rivets, which contributed roughly 80% across all impact categories. At the industrial scale, the balance shifted dramatically, with the operation stage responsible for 82% of impacts. Here, the main drivers were the large quantities of iron salts, sodium hydroxide, and TMAH required for continuous production, along with the substantial volumes of deionized water used for washing, which alone created notable resource scarcity impacts.

“Operation flowchart of the MNP synthesis at an industrial scale: (1) reagent solution production, (2) synthesis of MNPs, (3) magnetic separation, (4) washing, and (5) conditioning and storage.” Reproduced from Olga P. Fuentes, Juan C. Cruz, Emmanuel Mignard, Guido Sonnemann, and Johann F. Osma ACS Sustainable Chemistry & Engineering 2023 11 (18), 6932-6943 under Attribution 4.0 International License.

Wastewater analysis revealed that ethanol used in device assembly and TMAH in the stabilization step were significant contributors to marine eutrophication, toxicity, and other environmental categories. Transportation impacts also increased markedly in the industrial scenario, as raw materials would be imported over long distances. A sensitivity analysis suggested that replacing brass rivets with lower-impact connectors could substantially reduce the footprint at small scales, while improvements in chemical efficiency, water recycling, and wastewater treatment would be essential for sustainable industrial-scale production.

Ultimately, the study demonstrates that while microfluidic synthesis offers clear technical advantages for producing high-quality magnetite nanoparticles, its environmental profile depends heavily on the scale of operation and the materials and processes chosen. Small-scale systems could benefit greatly from design modifications to components, whereas large-scale facilities must focus on optimizing reagent use and water management to ensure that the benefits of microfluidics are not offset by avoidable environmental costs.

Reflecting on the broader significance of their findings, the authors conclude:

“This work represents a holistic understanding of the potential environmental impacts of MNP synthesis processes. Moreover, it paves the way for further analysis of the overall sustainability and eventual introduction of such emerging technologies into well-established manufacturing processes. Finally, this work is expected to help future environmental impact studies of nanomaterial production at the laboratory and industrial scales.”

Figures are reproduced from Olga P. Fuentes, Juan C. Cruz, Emmanuel Mignard, Guido Sonnemann, and Johann F. Osma ACS Sustainable Chemistry & Engineering 2023 11 (18), 6932-6943 DOI: 10.1021/acssuschemeng.2c06875 under Creative Commons Attribution 4.0 International License.

Read the original article: Life Cycle Assessment of Magnetite Production Using Microfluidic Devices: Moving from the Laboratory to Industrial Scale

For more insights into the world of microfluidics and its burgeoning applications in biomedical research, stay tuned to our blog and explore the limitless possibilities that this technology unfolds. If you need high quality microfluidics chip for your experiments, do not hesitate to contact us.